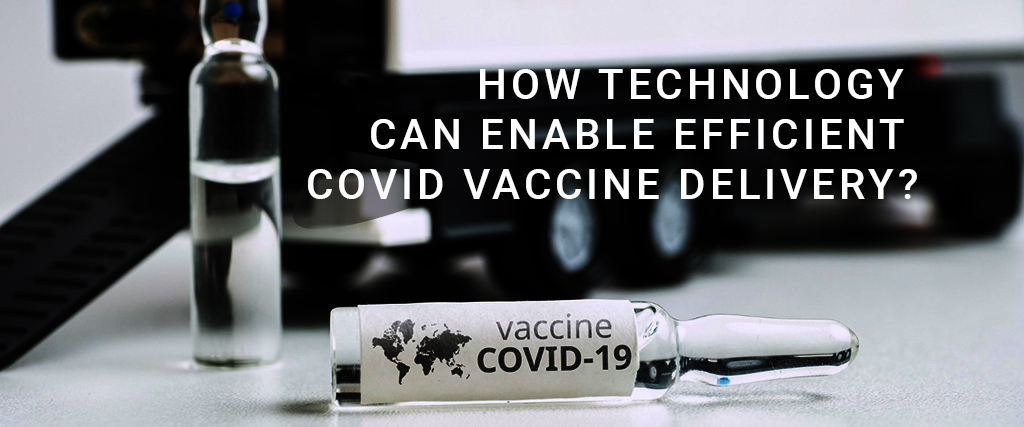

Vaccine Platform Technology: There are no human vaccines against any of the (now) 7 identified human coronaviruses, even though vaccines are unquestionably the safest way to combat infectious diseases.

Several firms, along with governmental and non-governmental agencies, began a rapid development campaign to produce a vaccine aimed at this virus as soon as the severity of the epidemic was recognized.

Vaccine production has historically been a lengthy process involving scientists tinkering with a pathogen to weaken or trick it so that it can induce an efficient immune response with minimal side effects.

In 2020, however, powerful new vaccine technologies will be available to supplement conventional vaccine production, allowing for the rapid delivery of a vaccine candidate for clinical trials to begin.

Vaccine Platform Technology: A Game-Shifting Innovation

Vaccine network systems are the latest technologies that are being used. Vaccine platforms allow you to make several vaccines from the same building blocks.

To put it another way, a Vaccine Platform Technology grants the opportunity to easily swap out the pathogen being targeted, much like a video game cartridge.

Indeed, the recently FDA-approved Ebola vaccine is based on another virus with the Ebola protein added.

The global vaccine rollout, which is currently underway, will be one of the year’s most important stories, and A.I. could play a role in at least four areas:

- Effect modeling and triage Identifying which population groups should be vaccinated in what order to effectively end the pandemic.

- Forecasting demand Choosing where and when to ship doses to inoculate as many people as possible in the shortest period.

- Supply chain management is a term used to describe the management of a supply chain. Bottlenecks in the vaccine development and distribution network are being monitored.

- Surveillance after vaccination. Looking for evidence of any vaccine-related side effects that were not discovered during clinical trials.

Vaccines Can Take Time to Develop

Despite the rapid development time made possible by vaccine platforms, clinical testing for protection, effectiveness, and dosing schedules will still take months.

Following this, the vaccine would need to be mass-manufactured in vast amounts to vaccinate the entire planet.

We cannot hope to see an approved vaccine for at least a year, if not longer if clinical trials do not go as expected.

When a vaccine becomes available, it will most likely be administered in batches to those most at risk for serious illness, such as the elderly and those with underlying disabilities, as well as healthcare staff.

Children tend to be less likely to develop the serious illness at this point, and they might not be the first to obtain the vaccine, however, if the virus persists (as predicted), coronavirus vaccination may become part of regular childhood vaccinations.

Data flow could be digitized – Vaccine Platform Technology

Developing a vaccine or a prescription therapy necessitates a massive amount of information.

It includes not only the usual concerns such as maintaining constant temperatures and pressures or adding the right amount of material at the right time, but also ensuring that the vaccine or pharmaceutical treatment progresses properly.

This information is compiled into a batch report. Previously, the data was stored on paper and could be hundreds of pages long, only for one batch.

All of this information is automatically captured as electronic batch history in the digital world.

Electronic batch records may help to reduce the amount of time that vaccines and prescription products are kept before being published.

Using the cloud to your advantage

Engineers can access a popular system from anywhere in the world, using the best talent regardless of venue, by configuring the control system in the cloud.

So, how does this shorten the time between conception and first production?

In certain ways, it helps you to delegate design decisions and essentially obey the light. You encourage engineers to work on the device at all times.

In parallel, one team will create and execute batch logic while another team works on the running displays.

At the end of the day, US engineers working on a vaccine will transfer information to an Indian team of engineers.

The team will work on the same device and then hand it over to another engineering team in Europe before returning to the United States.

Furthermore, several teams will work on different sections of the system at the same time, cutting down on the time it takes to complete the project.

This maintains the output momentum. Since you can operate in parallel, virtually simultaneously, it reduces the amount of time needed. It is not necessary to send engineers from all over the world to collaborate.

Enhance the user experience

Process operators were witnessed by marketing and technology teams as they struggled to operate processes on the legacy and competitive control systems.

One of the most important features of this updated visualization, for example, is that it shows how long a step is supposed to take.

For the next 45 minutes, a mixing operation will be run, followed by a manual addition to the batch. If the mixing process takes longer than expected, the operator is informed and advised to take corrective measures.

Traditional systems do not tell the user how long the procedure has been running or whether or not it needs to be corrected.

While the mixing process is running, the operator will perform other tasks such as taking a sample and sending it to the lab, staging an element that will be added later, and so on.

That is one of the main differences; it makes it much easier to grasp what is going on, what requires immediate attention, and what will require attention in the not-too-distant future.

Read More: HOW COVID-19 IS IMPACTING ON ECOMMERCE BUSINESS?