Machine Learning in Supply Chain: In a highly competitive market where organizations are continuously attempting.

To expand profit margins, cut expenses, and deliver superior customer experience, disruptive technologies like Machine Learning (ML) and Artificial Intelligence (AI) provide some excellent prospects.

To begin with, incorporating ml in supply chain management may assist automate a lot of monotonous operations and enable the organizations to concentrate on more strategic and significant business activities.

Using clever machine learning technologies, supply chain managers can optimize inventories and discover the best-matched suppliers to keep their firms operating effectively.

Today, a rising number of firms are exhibiting interest in the uses of machine learning, from its various benefits to fully harnessing the large volumes of data produced by warehousing, transportation systems, and industrial logistics.

It may also help organizations establish a comprehensive machine intelligence-powered supply chain model.

To manage risks, increase insights, and boost performance, which is critical to building a globally competitive supply chain model.

Machine Learning is a complicated but exciting topic that can tackle many challenges across businesses.

Being an intensely data-driven business, the supply chain offers various applications of machine learning.

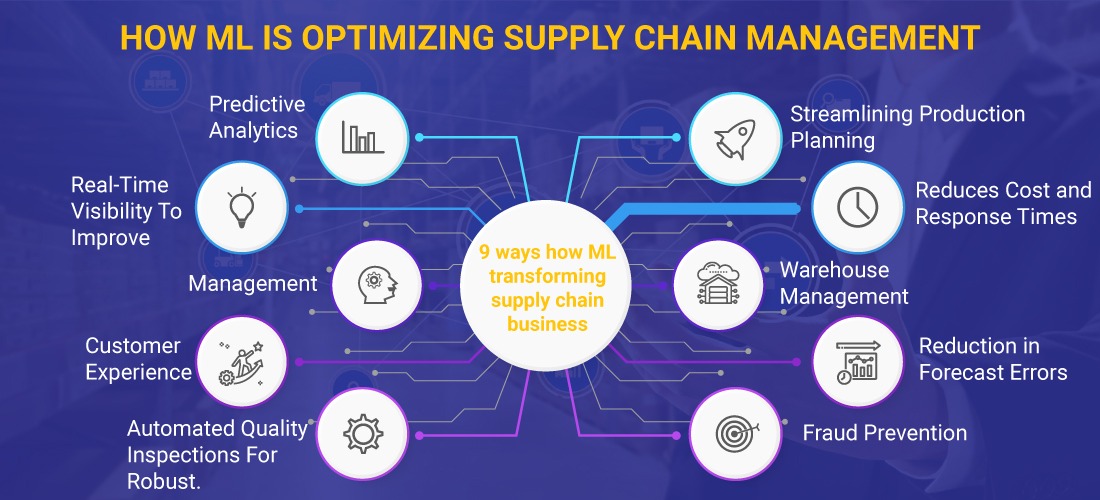

Elucidated here are the top 9 application cases of machine learning in supply chain management, which may assist push the sector towards efficiency and optimization.

Machine Learning in Supply Chain – Few ways In which ML Can Do Wonders

1. Predictive Analytics

There are various advantages of precise demand forecasting in supply chain management, such as lower holding costs and appropriate inventory levels.

These machine learning algorithms are good at recognizing hidden trends in past demand data.

A solid supply chain forecasting system means the organization is armed with resources and information to react to emerging challenges and risks.

And, the answer’s efficacy grows according to how rapidly the firm can respond to difficulties.

2. Automated Quality Inspections For Robust Management

Logistics hubs frequently perform manual quality checks to examine containers or products for damage during transportation.

Machine learning-enabled approaches allow for automated analysis of flaws in industrial equipment and to check for damages using picture identification.

The advantage of these power automated quality checks correlates to decreased possibilities of delivering defective or substandard items to clients.

3. Real-Time Visibility To Improve Customer Experience

A Statista poll highlighted visibility as an ongoing difficulty that grapples the supply chain firms.

Machine learning approaches, including a mix of deep analytics, IoT, and real-time monitoring, may dramatically increase supply chain visibility.

Thereby enabling organizations to alter customer experience and accomplish speedier delivery goals.

Machine learning models and workflows achieve this by assessing historical data from diverse sources and uncovering correlations between the operations throughout the supplier value chain.

An excellent example of this is Amazon leveraging machine learning methods to give a superior customer experience to its consumers.

ML achieves this by helping the organization acquire insights into the association between product suggestions and future website visits by consumers.

4. Streamlining Production Planning – Machine Learning in Supply Chain

Machine learning can play a vital role in optimizing the complexity of manufacturing planning.

Machine learning models and methods may be used to train complex algorithms on the previously existing production data to assist in the detection of likely areas of inefficiency and waste.

Further, applying machine learning in the supply chain in developing a more adaptive environment to cope with any interruption successfully is significant.

5. Reduces Cost and Response Times

A rising number of B2C organizations are employing machine learning methods to trigger automatic reactions and address demand-to-supply mismatches, thereby minimizing the costs and enhancing customer experience.

By enhancing communication with multiple logistics service providers and unifying freight and storage procedures, administrative and operational expenses in the supply chain may be decreased.

6. Warehouse Management

Efficient supply chain planning is typically linked with warehouse and inventory-based management.

Machine learning in the supply chain with its models, methodologies, and forecasting capabilities may also address the issue of both under or overstocking and entirely revolutionize your warehouse management for the better.

Using AI and ML, you can also examine massive data sets considerably quicker and prevent the errors produced by people in a typical case.

7. Reduction in Forecast Errors

Machine Learning acts as a powerful analytical tool to assist supply chain organizations in analyzing enormous data volumes.

Apart from processing such vast volumes of data, machine learning in the supply chain also guarantees that it is done.

With the most incredible variety and unpredictability, allowing telematics, IoT devices, intelligent transportation systems, and other similar sophisticated technologies.

This helps supply chain organizations to have far better insights and assist them in achieving accurate estimates.

Research by McKinsey also says that AI and ML-based deployments in the supply chain may cut prediction mistakes up to 50 percent.

8. Advanced Last-Mile Tracking

Last-mile delivery is a vital part of the whole supply chain as its effectiveness may directly influence numerous sectors, including customer experience and product quality.

Data also reveals that the final mile delivery in the supply chain contributes 28 percent of total delivery expenses.

Machine learning in the supply chain may give enormous chances by considering various data points like the approaches people use to input their addresses and the overall time required to deliver the items to specified places.

ML can also support improving the process and providing customers with more precise information on the shipping status.

9. Machine Learning in Supply Chain – Fraud Prevention

Machine learning algorithms can boost product quality and lower the risk of fraud by automating inspections and auditing procedures and conducting real-time analysis of outcomes to discover abnormalities or departure from regular patterns.

In addition to this, machine learning algorithms can also avoid privileged credential misuse, which is one of the leading causes of breaches throughout the global supply chain.

Final Words

Improving the efficiency of the machine learning in supply chain plays a significant role in every organization.

Operating their operations under strict profit margins, any form of process improvements may significantly influence the bottom line profit.

Innovative technology like machine learning makes it simpler to cope with the difficulties of volatility and anticipate demand correctly in global supply chains.

We at Yugasa Software Labs expect at least 50 percent of multinational enterprises in supply chain operations will be implementing AI and ML-related transformativetechnologiesby2023.

This is a testimony to the rising popularity of machine learning in the supply chain business.

Read More: THE USE OF MACHINE LEARNING IN MOBILE APP DEVELOPMENT